Get This Report on Tx Tees

Table of ContentsWhat Does Tx Tees Mean?The Buzz on Tx TeesSome Ideas on Tx Tees You Need To Know10 Simple Techniques For Tx TeesGetting The Tx Tees To WorkThe Best Guide To Tx Tees

The paper is very costly and can just be used when. Once it's published on, it has actually to be disposed of - embroidery shop. - The initial purchase cost is reduced than the ahead of time financial investment of DTG printers- You can publish multi-color designs one screen each time rather of needing to publish each shade separately like DTG printingScreen printers merely prepare their display after that start publishing up until they lack item or ink.- There is a broad variety of seasoned display printers all over the world, which can be helpful for beginners. - It's a slower process - screen printers typically have to wait on the ink to completely dry prior to they can publish the following shade- Display printers call for manual work, so there's a higher knowing curve and it takes longer to produce a top notch layout- Display printing isn't as exact as DTG printing, so you might obtain some "blood loss" of colors from one part of the image onto another if not done properly.

However, as opposed to utilizing screen mesh as screen printers do, dye sublimation printers use laser modern technology to move your photos onto garments or paper - https://www.pageorama.com/?p=txtees02. A warmth process moves the dye from its solid-state directly right into the gas stage which consequently fuses it onto textile substrates when they are quickly warmed to high temperatures under high pressure

Tx Tees Things To Know Before You Get This

Sublimation printing is eco-friendly. It utilizes much less water than screenprinting, and because it doesn't involve using dangerous solvents, it's safe for all sorts of apparel. The color sublimation inks are likewise unsmelling when cured, unlike screen printers that use hazardous chemicals during the screen printing process that leave an undesirable smell.

They also save money on pricey devices like exposure devices considering that dye sublimation printers don't require a UV direct exposure system or a flash treatment stove that is generally made use of in display printing. What is direct to garment printing (DTG Printing)? DTG printing is an electronic screenprinting process that publishes directly onto textile utilizing specialized inkjet printers.

DTG printing offers lots of benefits over typical screenprinting, including the capability to publish photographic high quality pictures, better color vibrancy, and the capability to print layouts on darker fabrics. DTG printers function by heating the textile ink until it becomes a gas. The gas after that permeates the textile, bonding with the fibers to create a long-term print.

The Main Principles Of Tx Tees

The display is reusable and can be utilized lot of times before needing to be replaced. When contrasting prices on which printing procedure to make use of, display printing is usually the most popular choice. With display printing's appeal comes its negative aspects - generally in the cost of prints and arrangement time entailed.

While display printing can commonly produce better outcomes, it additionally takes 3x much longer for each and every print contrasted to DTG. This means that screen printers are regularly sitting at their presses waiting on tasks to come in before they work on them. With screen printers just having the ability to generate 6-12 items per hour depending upon complexity, can build up quickly and become a more expensive alternative than DTG printing.

Without setup fees, DTG printers are a fantastic alternative for little services and specific clients that intend to print a few tee shirts without investing a great deal of cash. Furthermore, there is no minimal order quantity, so print stores with these digital printers can generate one t-shirt at a time without any type of additional fees.

Some Of Tx Tees

Repainting the pattern onto the mesh making use of 'display blockers' such as glue or lacquer. Designs made using the screen printing technique may use just one shade of ink, or a number of.

The ink or paint likewise hinges on layers on the surface of the fabric or paper, which gives the print a nicely responsive high quality. The technique is additionally favoured due to the fact that it enables the printer to easily recreate a style numerous times. Since the exact same pattern can be utilized to duplicate a layout time and again, it's very valuable for producing multiple duplicates of the exact same garment or device.

When performed using professional equipment by a skilled printer, it's additionally feasible to create complex multicoloured designs. While the intricacy of the process does mean there's a restriction to the number of colours the printer can make use of, it does permit even more intense colouring than is feasible to achieve with electronic printing alone.

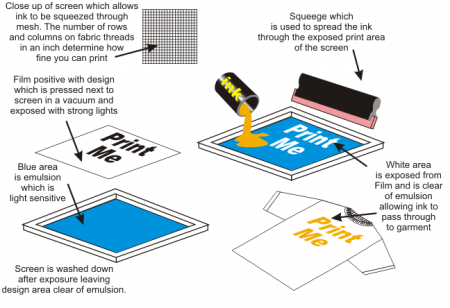

To start, the printer takes the layout they want to develop on the finished item, and prints it out onto a clear acetate movie. This will certainly be used to develop the stencil. Next off, the printer will certainly choose a mesh screen to match the complexity of the style, and the appearance of the material being published.

Tx Tees Fundamentals Explained

The acetate sheet including the design is then laid onto the emulsion-coated display, and the entire point is exposed to a very brilliant light. The light sets the emulsion, so the parts of the screen which are covered by the design stay in liquid type. If the last style is going to include more than one colour, then a different display needs to be utilized to use each layer of ink.

After the display has actually been revealed for an established time, the locations of the display not covered by the design will certainly have transformed hard. Any unhardened emulsion is after that thoroughly rinsed away. This leaves a clear imprint of the style on the screen for the ink to go through. The screen is then dried, and the printer will make any necessary touch-ups or adjustments to make the imprint as exact as feasible to the initial layout.

The display is then put on the printing press. The product or garment being published is set flat onto the printing board, underneath the display. There are a number of different presses, consisting of handbook and automatic styles, yet many modern business printers will certainly utilize an automatic rotating carousel printer, as this allows several various screens to work at as soon as.

Our Tx Tees Ideas

The display is lowered down onto the printing board. Ink is included in the top end of the display, and a squeegee is used to draw the ink along the full length of the display. This presses the ink through the open locations of the stencil, inscribing the layout on the product below.

To obtain a clean, sharp print, a screen printer needs to have the right tools for the work. Below, we'll discuss every piece of display printing devices, including what function they serve during the printing procedure. While it is feasible to screen print with simply a mesh screen and a squeegee, many printers favor to utilize a press, as it permits them to print lots of things a lot more effectively.